Glycol Beer System Maintenance

Learn more about troubleshooting your glycol cooled draft beer system.

Glycol beer system maintenance. Have you ever cracked open an ice cold beer or tapped into a brand new keg and thought wow this is refreshing. To ensure a beer system is functioning properly follow these guidelines. Measurements of glycol concentration. A quality product is the result of a well maintained system.

Rather than risking breakdowns during your busiest period regular maintenance can help your equipment run more efficiently and identify problems before they disrupt your business. Glycol cooled draft beer dispensing systems are typically used in commercial applications such as bars restaurants and stadiums. It is important to keep your system maintained at all times to prevent it from breaking down. But still no one wants to be served a room temperature glass of brew when they expect something a bit frostier and more refreshing.

The glycol system only requires you to clean your beer lines once every 4 weeks as opposed to the currently recommended once every week. Having regular maintenance of your glycol or direct pull beer system can reduce running costs wastage and increase the life span of your beer system. That is why glycol systems exist. Maintain proper freeze point levels.

Operating with a 35 glycol to 65 water solution typically will protect from freeze up to 1 f the proper propylene glycol to water ratio mixture is very important in your chiller system. Unfortunately if the glycol system is not working then customers will not be happy and business will suffer. That s the long and the short of it. Since glycol has a lower specific heat than water higher concentrations of glycol in your closed loop water will reduce the heat carrying capacity of the system.

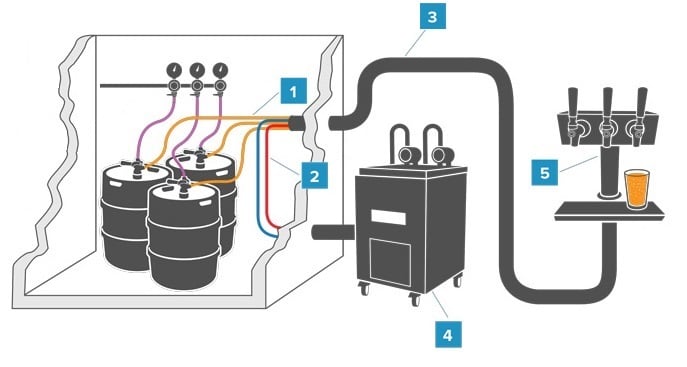

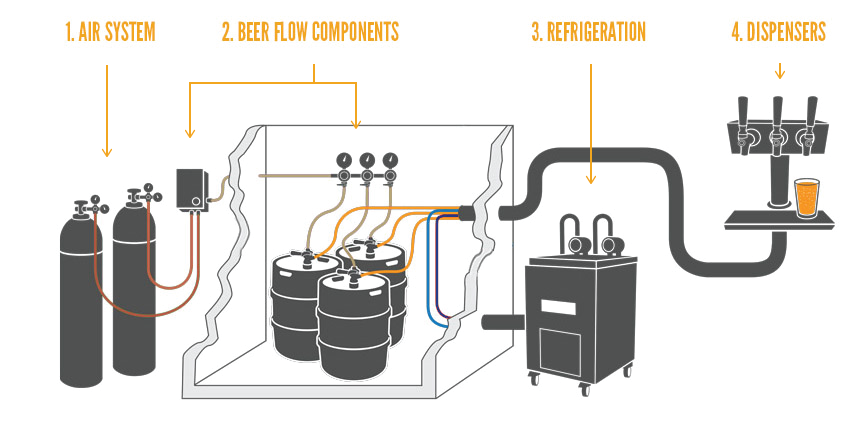

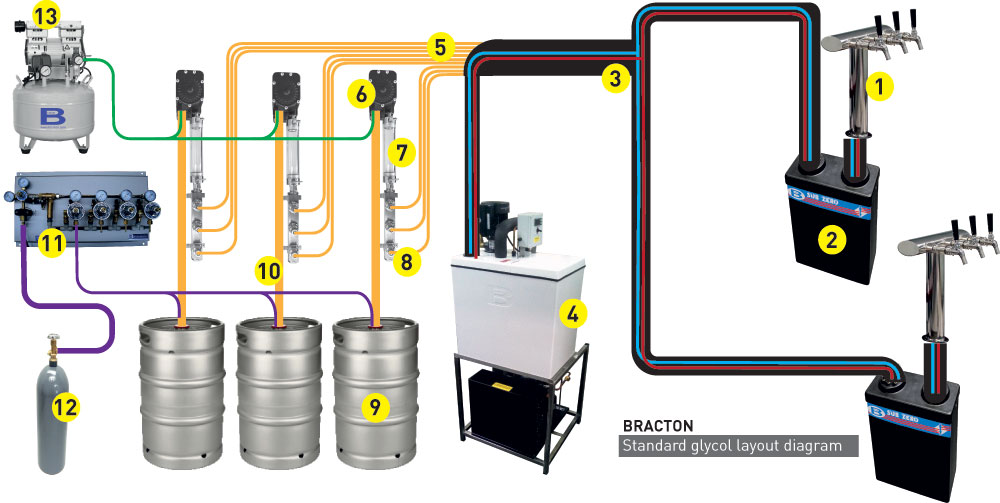

These systems use a secondary refrigeration unit called a power pack or glycol chiller to maintain draft beer at the proper temperature all the way from the walk in cooler to the point of dispense. The beer tap system is one of the most important tools in a bar nightclub or restaurant so it s important that you re properly maintaining your system. They keep beer cold so that bars can serve the frostiest beverages possible to their clientele. This is done by the power pack chilling and constantly.

As the craft beer revolution has taken root the emphasis on the colder the better has certainly waned. Too much glycol will therefore increase energy costs as the system works harder to accomplish the desired heating or cooling. Too much glycol inhibits system efficiency. Direct draw maintenance self contained keg beer storage and dispensing system.

Too little glycol can lead to a costly freeze up. This means lower maintenance cost and cheaper keg prices from major breweries at home or from overseas. Clean the system a minimum of every 14 days. Maintain a consistent beer temperature of 38 f.